Description:

Bruce Shapiro got me to design

and build the UBW (USB Bit

Whacker) project to solve his problem of disappearing parallel

ports on computers. The UBW design has exceeded all of my expectations.

As well as meeting the original design objectives, it has proven

itself a great platform for many forms of firmware. But there was

still a problem! Bruce traditionally used the UCN5804B stepper motor

driver chip for his EggBot

classes because it is easily breadboardable and very simple to

use. Unfortunately, they are now $17 each and very difficult to

find. Bruce wondered if I could design and build a replacement

driver that would still be mountable on a breadboard, would still

just need two input lines (step and direction) and would drive

bi-polar stepper motors. And so now we have the EasyDriver design.

There is now an official EggBot

that you can purchase! It uses an EiBotBoard, which I

designed and consists of a UBW + 2 BigEasyDrivers. The EiBotBoard is

now available for purchase at SparkFun

and Evil Mad

Scientists.

Knock-Off Easy Drivers

Over the years, the Easy Driver has become popular enough that

lots of people have copied it and are making and selling it. I am

flattered, truly I am. And this is open source hardware after all.

However, any other manufacturer of Easy Drivers besides SparkFun

and SeeedStudio are doing so without supporting me in any way,

which means I then have fewer resources to design new OSHW. The

license that the EasyDriver is released under requires at least

some attribution. These knock-off manufacturers will normally

strip off the "SchmalzHaus.com" silk screen before they build

'their' boards, see for example Electronics

DIY. It appears that Electronics DIY has decided to build

Easy Drivers, taking off the "Schmalz Haus" part of the silk

screen, and not mentioning anywhere on their page where the design

came from (i.e. no 'attribution'). This is in violation of the

license. There are lots of others too - all of the very

inexpensive EasyDrivers that are now on EBay, Amazon, and

Aliexpress are knock-offs. None of them support me in any way, but

I end up fielding tech support for their boards because people

write to me with questions. So please help support OSHW and buy

from SparkFun or SeeedStudio. They are fantastic and not only

believe in the value of OSHW but actively support designers like

me.

Quick Specs:

Each EasyDriver can drive up to about 750mA per phase of a bi-polar

stepper motor. It defaults to 8 step microstepping mode. (So if your

motor is 200 full steps per revolution, you would get 1600 steps/rev

using EasyDriver.) This setting can be easily overridden by tying

the MS1 and/or MS2 pin to ground to set the driver to use 1/8, 1/4

or 1/2 microstep mode (See the datasheet for the table of values).

It is a chopper microstepping driver based on the Allegro

A3967 driver chip. For the complete specs of the design, read

the A3967 datasheet. It has a variable max current from about

150mA/phase to 750mA/phase. It can take a maximum motor drive

voltage of around 30V, and includes on-board 5V regulation, so only

one supply is necessary. The best part - low cost. The parts cost is

easily less than $10, even less if you make the board yourself.

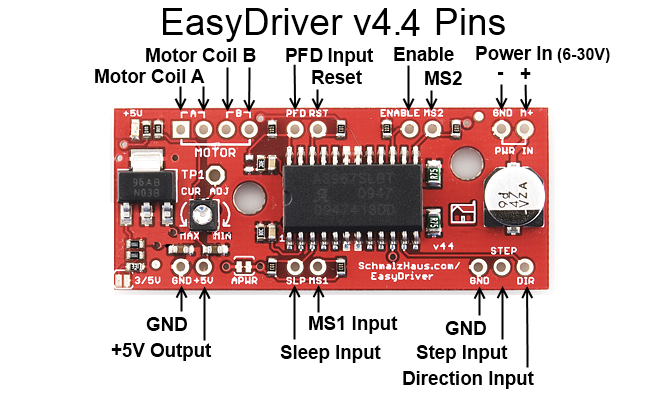

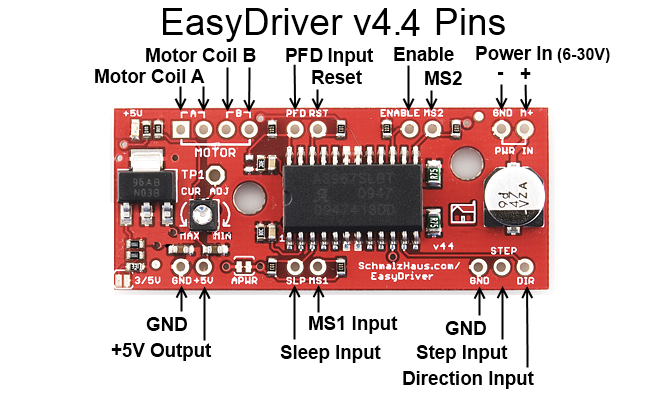

Quick Pin Description:

Please see the Allego A3967 data sheet linked above for complete

technical details. The Easy Driver is basically just a breakout

board for this driver chip, so the datasheet is your best source of

information about how it all works. However, if all you need is a

reference to the pins, here you go:

- GND : There are three GND (Ground) pins on the Easy Driver.

They are all connected together inside the board. Connect the

negative side of your power supply, as well as from any other

boards you are using to drive the Easy Driver to one or more of

the GND pins.

- M+ : This is the power input to the Easy Driver. Connect this

to the positive power supply lead. This should be a 6V to 30V,

2A (or more) power supply that is clean (low ripple).

- A and B : (four pins) These are the motor connections. See

below diagrams for how to hook these up. A and B are the two

coils of the motor, and can swap the two wires for a given coil

(it will just reverse the direction of the motor). Make CERTAIN

that this connection to the motor is solid, and NOT through a

connector that has any chance of intermittent contact (which

will fry the motor driver chip).

- STEP : This needs to be a 0V to 5V (or 0V to 3.3V if you've

set your Easy Driver that way) digital signal. Each rising edge

of this signal will cause one step (or microstep) to be taken.

- DIR (Direction) : This needs to be a 0V to 5V (or 0V to 3.3V

if you've set your Easy Driver up that way) digital signal. The

level if this signal (high/low) is sampled on each rising edge

of STEP to determine which direction to take the step (or

microstep).

That's it - those are the only signals that you absolutely need

to connect to anything. All the rest below are optional - in other

words, the Easy Driver sets them to reasonable default values.

- MS1/MS2 : These digital inputs control the microstepping mode.

Possible settings are (MS1/MS2) : full step (0,0), half step

(1,0), 1/4 step (0,1), and 1/8 step (1,1 : default).

- RST (reset) : This normally high input signal will reset the

internal translator and disable all output drivers when pulled

low.

- SLP (sleep) : This normally high input signal will minimize

power consumption by disabling internal circuitry and the output

drivers when pulled low.

- ENABLE : This normally low input signal will disable all

outputs when pulled high.

- PFD : This one is complicated - please see the datasheet for

more information. We default it to slow decay mode, but you can

over-ride with your own voltage on this pin. (or by populating

R17)

- 5V : This is an OUTPUT pin that will provide either 5V

(default) or 3.3V from the voltage regulator, at a small amount

of current (say 50mA - depends on input voltage) to power a

circuit that you may need powered. If you cut jumper APWR (SJ1)

then you can use the 5V pin as a VCC input to the Easy Driver,

powering it with your own VCC supply.

Oh, so awesome: where can I buy one!

I do not sell EasyDriver boards. This design is open source hardware

released under a creative commons license. It was developed in

conjunction with SparkFun, and they manufacture and sell it.

I'm providing Eagle schematic and board layouts as well as a Bill Of

Materials and instructions on how to build and use the design if you

want to take the design and modify it for your own use. If you do

decide to manufacture the EasyDriver for yourself or for sale,

please remember that royalties are the only way that I can continue

to provide support to Easy Driver users, so contact me.

SparkFun DOES sell EasyDriver

boards and they're only $15 each!

Also, please note that a Bigger, Badder, and all around Better

version of the Easy Driver has been designed. It's called the Big

Easy Driver (BED). You can read all about it at the Schmalz Haus Big Easy Driver

page.

News:

(08/18/2015) Added a new

section to the FAQ below about the two jumpers on the Easy Driver

and what they do. (Q15)

(11/16/2012) I did some measurements of temperature and current draw

with a SparkFun stepper motor and an EasyDriver. See the results

lower down this page, under Question 14.

(10/13/2012) Xavier wrote a great tutorial on using Easy

Drivers with Arduino.

(07/20/2012) MyDIYCNC is

now using Easy Drivers in some of their products, and is even

selling the driver boards in their store. Check out their cool CNC

machines.

(02/11/12) New Easy

Driver and Big Easy Driver Examples page - with Arduino code,

diagrams, etc.

(02/11/12) On a whim, I tested to see what the lowest voltage is

that the Easy Driver could run on. It had no problem running down to

about 4V (this is with a factory fresh Easy Driver 4.4). And, it ran

really cool. Note that you'll need a very low coil resistance motor

to make this work very well unless you are using full or half steps.

(01/03/12) Very minor update to schematic and BOM for EasyDriver

v4.4 - C3 is now 47uF. (SparkFun has always build them with 47uF

caps, but I've updated the documents to reflect this. It was

previously listed as 100uF.)

(08/19/11) We now have an Eagle

part library with the EasyDriver v4.4 in it for anyone who

wants to plunk down EasyDrivers on their board.

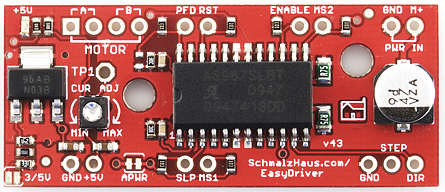

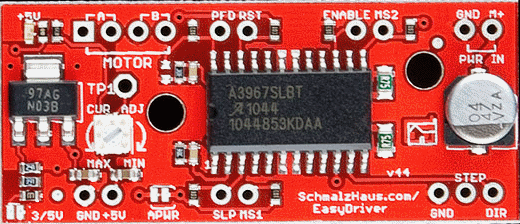

(08/03/11) It appears that there are two different types of current

adjustment pots being used for EasyDriver v4.4 production. If you

have one with the squarish white box of a pot (as per the v4.4

picture on the top of this page) then your MIN and MAX silkscreen

will be backwards. The previous version of the pot (see v4.3 pic)

has its pins in the right place, so that the MIN and MAX silk screen

labels are in the proper place. I don't know why the pot vendors

would choose to make their parts backwards, but that's how it goes.

Anyway, be careful. Note, the board is identical, it's only that one

pot is designed backwards from the other.

(10/21/09) Note that v4.3 and v4.2 (and possibly others) have the

MIN and MAX words backwards on the board. So if you have a small

motor, be CAREFUL! The likely result is that you will set it to MIN,

but a full 750mA will go through your motor, and it will get quite

hot. There will be a new v4.4 soon which will fix this problem.

(12/02/09) Version 4.3 has now been released to SparkFun - only

difference being two mounting holes.

(10/01/09) After a very long process (due to my procrastination and

schedule) we finally have a new

version of the EasyDriver! In very close collaboration with

SparkFun, I'm happy to release version 4.2 to the world. This new

version has several very nice new features, and still has the same

great price, $15! Thanks Spark for making this design available to

the world. (Some pictures on this page are from SparkFun.)

(09/17/08)Daniel Thompson has created an awesome

tutorial (with movie) on using the EasyDriver with an Arduino

to run stepper motors! Thanks Daniel!

NOTE: Many people attempt this setup without connecting the grounds

of the power supply, EasyDriver and Arduino (or other pulse source)

together. It tends to not work that way! So make sure you always

connect the grounds, and you'll have much better luck.

(5/23/07) Added project files for V3 design.

(4/6/07) Initial webpage created. Documents V1, V2, and V3

design revisions of EasyDriver board.

Easy Driver downloadable design files:

Version Notes:

- EasyDriver V1 - This was the first attempt. I had two boards

fabbed at BatchPCB (Very

highly

recommended). The design worked fine but because the board was

so small it got _way_ too hot. Also did not have variable

current limit or 5V regulator.

- EasyDriver V2 - This was the second attempt. I had some boards

fabbed at Futurlec

without solder mask or silkscreen. The board was twice the

size of V1, and routed to dissipate heat much better. The 5V

regulator was added. I have since modded the completed boards to

add the variable current limit.

- EasyDriver V3 - A refined version of V2, with the variable

current limit on the board, and switched to 0603 components. I

have not had any of these boards fabbed yet, as I'm confident in

the design from the V2 boards. - Update: SparkFun is now selling

these, and they work fine.

- EasyDriver V4.2 - Same footprint (as far as the holes go),

slightly longer board, with lots of new features. Here are the

difference from V3:

- Every I/O pin on the driver chip now comes out to headers,

and is pulled up (or pulled down) with 10K resistors. This

means you can now control every aspect of the driver chip

yourself. You can change MS1 and MS2 to do full step, half

step, quarter step or 1/8th step. You can put the chip to

sleep or in reset (drastically reducing power consumption).

Also, you get to play with PFD signal.

- That horrible tiny pot from V3 is now a somewhat larger pot.

:-) The really nice thing is that it doesn't have continuous

rotation, so you know where MIN and MAX current are

(finally!).

- A power-good LED has been added so you know when the

EasyDriver has 5V from the on-board regulator.

- A ground pin has been added next to the STEP and DIR pins.

This allows for a 3-pin cable to your Arduino or whatever you

use to drive the EasyDriver.

- By soldering SJ2 closed, you can switch the logic supply

voltage for the EasyDriver from 5V to 3.3V. This allows

interfacing with things like 3.3V Arduinos or other processors

that only output 3.3V.

- If you want to supply your own logic power to the

EasyDriver, cut jumper SJ1, and supply 3.3V or 5V into pin 1

of JP4.

- If you want the EasyDriver to power some small circuit, you

can use the 5V (or 3.3V) coming from pin 1 of JP4. How much

current can you pull from here? Well, feel the regulator. If

it is uncomfortably hot, then you're using too much. How hot

it gets depends upon what voltage you supply to the

EasyDriver.

- TP1 allows you to put a meter on the VREF signal as you turn

the current adjust pot. Measuring this voltage allows you to

calculate the actual max current being supplied to the motor.

See the schematic for information on how to do this math. I

never do this myself - I adjust the pot until things 'feel'

right on my motors since every situation is different.

- The value of the bulk cap is listed at 100uF on the

datasheet, but 47uF is all that is really necessary. The

bigger the better - but the Allegro datasheet says 47uF is

fine. SparkFun may use 47uF caps on their boards and that's

OK.

- EasyDriver V4.3 - Exactly the same as V4.2 except two mounting

holes have been added based on user requests.

- EasyDriver V4.4 - Exactly the same as V4.3 except the MIN/MAX

silk screen error has been fixed (well, not really, since the

current adjustment pot got changed) See note Q9 below.

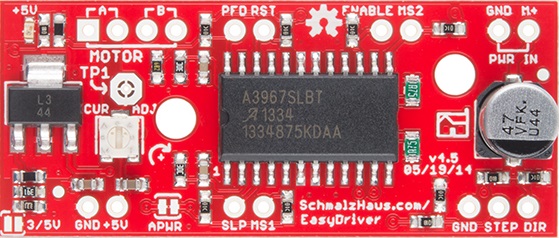

- EasyDriver v4.5 - Major change from v4.4 was the addition of

series current limiting resistors on STEP and DIR as well as

pull downs on STEP and DIR. This helps prevent damage during

over voltage events.

Common Questions and Answers:

Q1) My motor says it can only take

2.1V at 2A. Will the EasyDriver (running from up to 30V) blow up my

motor or damage it in any way?

A1) Nope. You're safe.

Motors are specified with DC flowing through their coils. But what

we are concerned with is maximum current. The voltage spec of the

motor doesn't really matter, using the EasyDriver. (Or any chopper

driver, for that matter.) The EasyDriver will ramp up the voltage to

the coil until the _current_ reaches the maximum set with the pot

(max of 750mA). Then it will cut the power to the coil until the

current dips down again, then re-apply power, over and over again,

about 20,000 times per second. Any motor that's rated for 150mA/coil

(or more) will work with the Easy Driver just fine, no matter what

it's voltage rating. Note that if your motor is rated for less than

750mA/phase, you should adjust the current set pot on the EasyDriver

to dial down the maximum coil current to match your motor.

Q2) So

shouldn't I run the power to the EasyDriver at the voltage that my

motor is rated for? (i.e. 2.1V as per the above example)

A2) No. The voltage rating

of the motor DOES NOT MATTER. Really. Trust me on this. At least to

a point. You want to run the EasyDriver with as high a voltage as

needed for your application. Lower voltages produce a lot less heat

(on the ED and the motor) but produce lower maximum speed and

torque. Higher voltages (up to 30V) get you more torque at higher

speeds, but your ED will get much hotter. You make the decision.

Also, the higher the input voltage, the greater chance of frying

your ED if your motor wires come undone for some reason. Most people

are perfectly happy running their ED at 12V, and there are tons of

power supplies that work great at 12V and are cheap. The technical

reason for this is that the Easy Driver is acting like a switching

power supply. It is stepping down the voltage and stepping up the

current. The coil of the motor is basically like the inductor in a

buck converter. The chopper circuit switches the coil voltage on and

off to maintain a constant current through the coil.

Note that you can run the EasyDriver with a supply voltage of as low

as about 3V. This does NOT mean that you will get good stepper motor

performance at that voltage (actually, I can almost guarantee you

will not). However, even at 7V or 9V, the torque on most stepper

motors is near their max, at lower speed. Where you really need the

higher input voltage is at higher step speeds.

Another important point that a lot of people don't realize is that

many times, you don't really need the full, rated torque of the

motor for your application. For example, the small stepper motor

from SparkFun (https://www.sparkfun.com/products/9238),

develops a very large percentage of its fully rated torque even with

9V of input to the Easy Driver and the current adjustment turned all

the way down to 150mA/coil. In other words, you probably don't have

to break you back trying to make out the motor's rated current, and

thus rated torque. Try it in your system first - you may be

surprised with how much torque can be generated with a smaller

current and voltage.

Q3) How

much current does my power supply need to produce?

A3) The max that the

EasyDriver can shove into the motor is 750mA/coil. With 2 coils per

motor, that's 1.5A. So your power supply needs at least 1.5A to be

completely safe. However, you can normally get away with less than

that and still be just fine. Because of the way a chopper driver

works, the driver and motor actually form a sort of switching power

supply. Let's say that in order to reach 750mA/coil, the ED needs to

only ramp up the voltage to the coil to 6V. So if you're supplying

the ED with 12V, then the driver is working like a step down power

supply from 12V to 6V (we're sweeping a lot of things under the rug

here, but stick with me) so we only need to supply it with half of

the current it's sending to the motor (because the voltage is cut in

half, we only need to supply half the current going into the motor).

So in this case, you'd only need a power supply of 750mA. The best

advice here is to experiment. If your power supply is not 'strong'

enough, the voltage will dip and you will drop steps. (i.e. not

enough torque to keep the motor in the commanded position).

See the table under question 14 below for some experimental data I

took.

Q4) So why

does my bench power supply show 12V at 400mA when I know my motor

should be drawing 750mA/phase (1.5A total)? Huh smarty pants?

A4) See above answer.

Because of the way a chopper drive works is the real answer. You can

NOT trust any sort of power supply current measurement in order to

measure the actual coil current at any point in time. In actuality,

it is really hard to measure the actual current being delivered to

the coil, even if the motor is not moving. You need a special amp

meter attachment for a scope. The ones I've used at work are about

$5K each. (just for the stinkin' probe) So we just rent them when we

need them.

Also, see table under question 14 below for actual data supporting

this answer. The coil current is not equal the power supply current.

(Power supply current is always less than the sum of both coil

currents.)

Q5) How do

I adjust the current limit?

A5) Just turn R16 - the 10K

current limit pot. At one limit, it will tell the driver chip to

supply up to 750mA (limited by coil resistance and input voltage)

per coil. At the other limit, it is 150mA/coil. More recent

EasyDriver boards have silk screen words MIN and MAX, but you can

not trust them. This is because we can never be sure what pot

SparkFun uses to build the boards, and some pots are backwards from

the others. So always measure the voltage at TP1 and use that as

your guide for knowing which way is MAX (maximum TP1 voltage) and

MIN (minimum TP1 voltage).

Q5.1)

What kind of stepper motors can I use EasyDriver with?

A5.1) The Allegro 3967

driver chip that the EasyDriver is based off of is a bi-polar

driver. This means it has a true H-bridge design internally, and

sends current both ways through each of the two coils. You can use

4-wire, 6-wire or 8-wire stepper motors. The only kind you can't use

is 5-wire stepper motors. (They need uni-polar drivers.)

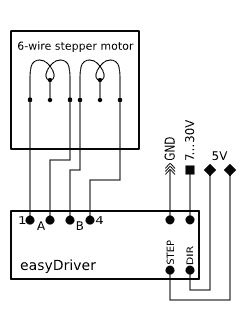

Here's a little drawing on one way to hook up a six wire stepper

motor to the EasyDriver.

Q6) Why

does EasyDriver get so hot?

A6) PWM current limiting

drivers (so-called 'chopper' drivers) are turning the coil currents

on and off very rapidly. This makes sure that the maximum amount of

current (as set by R16, the current set pot) is _always_ flowing

through the coils of the stepper motor, even if it is not moving at

all. That's just how these things work. It means that the driver is

constantly passing that much current through, and because its

internal resistance is not zero, it dissipates some heat. If you

turn R16 all the way up so that 750mA flows through each coil, the

entire EasyDriver board will get hot to the touch. I've never burned

my finger on it, but it certainly gets hot. (At the minimum - about

150mA/coil - it only gets barely warm.) You can put a small fan

blowing across the board if you want to. But fear not, the driver

chip has a thermal cut out at 165 degrees C, so it will protect

itself. The boards have quite a bit of copper pour on them, to

maximize heat dissipation, which helps a lot. Also the voltage

regulator gets quite hot - this is because the driver chip needs

70mA at 5V for its logic supply. Depending upon what voltage you use

into the M+ pin, the voltage regulator needs to drop that down to 5V

(and throw the rest away as heat). So the higher the M+ voltage, the

hotter that regulator will get.

For actual quantitative data, see question 14 below.

Q7) What

hardware/software can I use to test my EasyDriver?

A7) Here's what I do. I

solder headers in the pins of the EasyDriver and put it into a

breadboard. I solder the wires on my stepper motor to a 4-pin .100"

male header, and plug that into the breadboard so it connects

properly to the EasyDriver. Then I take a PC power supply, and use

the 12V from that into the GND and M+ pins on the EasyDriver. Then I

tie the DIR pin to Ground with a wire. Then I take a square wave

with a frequency of about 500Hz and put it into the STEP pin. This I

generate with a signal generator or an Arduino or UBW. The motor

should be spinning at this point. You can then take the DIR pin and

connect it to +5V to see the motor go in the other direction. As the

motor is running, you can slowly adjust the current adjust pot to

see the effect that it has on the smoothness of the motor's motion.

Q8) How do

I connect my EasyDriver up?

A8) (For Version 4.2 and above) All

of the pins on the EasyDriver are on a .100" grid. If you solder

.100 headers into the pins you want to use, it plugs into a standard

breadboard. Once you plug it into a breadboard, you can then plug in

your stepper motor to the four motor pins (JP3), your 8V to 30V

motor power to the GND and M+ PWR IN pins (JP1), and your Step and

Direction signals to the STEP, DIR and GND pins (JP2). The GND pin

in the lower left corner of the board is really only there for

mechanical support, but it is tied to ground and you can use it as

such if you want. You could also construct a simple 'carrier' board

(on a proto board or some such) with female .100" headers for all

for the EasyDriver pins. Then it would be easy to wire up as many

EasyDrivers as you wanted to drive lots of stepper motors.

A8) (For Version 3) All nine of the

pins on the EasyDriver are on a .100" grid. This means it plugs into

a standard breadboard. Once you plug it into a breadboard, you can

then plug in your stepper motor to the four motor pins (JP4), your

5V to 30V motor power to the GND and V+ pins (JP1), and your Step

and Direction signals to the STP and DIR pins (J3). The GND pin in

the lower left corner of the board is really only there for

mechanical support, but it is tied to ground and you can use it as

such.You could also construct a simple 'carrier' board (on a proto

board or some such) with female .100" headers for all for the

EasyDriver pins. Then it would be easy to wire up as many

EasyDrivers as you wanted to drive lots of stepper motors.

Q9) My

Easy Driver's labels don't match what I see in the picture. Why not?

And how do I know which way to turn the current adjustment pot?

A9) There are some mistakes

with the EasyDriver silk screen on previous board revs. On some of

the earlier versions the STEP pin is not labeled, and the motor coil

output pins are not clearly marked. This diagram should help clear

up any problems:

One important thing to note is

that, on various versions, I've gotten the silk screen for the

MIN/MAX of the current adjustment pot backwards and SparkFun has

used various potentiometers that have reversed directions (thus

making the 'correct' silk screen backwards again). SO! You never

really can trust the silk screen on the Easy Driver. Instead,

what you need to do is put a volt meter on the TP1 test point

(which is connected to the VRef pin on the driver chip) and

measure its voltage with respect to ground. The largest voltage

on that test point (normally 5V) will result in the largest

current through the motor coils (750mA), and the smallest

voltage on TP1 (1V) corresponds to the least current through the

motor coils (150mA).

Q10) Man,

this is a lot of work to just use the A3967 chip. Can't I just

solder down a bunch of A3967s on my own board design and save a ton

of money?

A10) Sure. <grin> The

EasyDriver board is for people who want to spend a little bit of

money and not have to worry about making their own board to hold the

driver chip. It is for people who want a design that will 'just

work' instead of having to try stuff out for themselves. It is for

'software folk' (like myself) who want to spend time writing code,

not debugging hardware. It is for people who want to build an EggBot

but can't get the 5804B chips. If you're designing your own board,

then don't use an EasyDriver! Just put the chip down on your own

board yourself.

Q11) The

datasheet for the driver chip shows that the motor connects to pins

OUT1A, OUT1B, OUT2A and OUT2B, and the diagram in the datasheet has

one coil connected across OUT1A and OUT1B, and the other across

OUT2A and OUT2B. But the Easy Driver only has A, A, B, B for

motor connections, and it looks like one coil should be connected

across the two A pins and the other across the two B pins. What's up

with that?

A11) Yeah. Ooops.

Clearly that was a pretty bad choice for the Easy Driver labels. On

a bi-polar stepper motor, there are four wires that connect to two

coils. Each coils has two wires. The Easy Driver calls those two

coils A and B. So one coils' wires are to be connected across the

two A pins, and the other coils' wires are to be connected across

the B pins. The driver chip datasheet refers to these two coils as

coil 1 and coil 2. Sorry for the confusion. See the diagram above

for the accurate connection diagram for the Easy Driver.

Q12) So

what's the deal with microsteps? How do I set what number of

microsteps are used?

A12) Microsteps are a way to

take a single, full step, and break it down into smaller steps. The

A3967 driver chip carefully controls the current to each coil to

cause the rotate to move to positions in between the normal full

step positions. This allows for smoother motion, reduced mid-band

resonance, and higher positional accuracy and resolution at the

expense of a more complicated driver and somewhat reduced torque.

The Easy Driver is able to operate in 1/8th, 1/4, half, and full

step (2 phase) modes. These four modes are selected by the logic

levels on the MS1 and MS2 input pins. Normally, the pull-up

resistors on the Easy Driver hold MS1 and MS2 high, which results in

a default setting of 1/8th microstep mode. You can pull either

or both to ground to select the other 3 modes if you want. See the

table below:

MS1

|

MS2

|

Resolution

|

low

|

low

|

Full Step

(2 phase)

|

high

|

low

|

Half step

|

low

|

high

|

Quarter

step

|

high

|

high

|

Eight

step

|

Q13) Help!

I think my Easy Driver is not working like it should. How can I know

if it's become damaged?

A13) One thing you can do

is to measure some of the resistances and voltages on the board to

see if it has become damaged.

- With everything

disconnected from the ED, measure the resistance from each

of the four motor output pins to GND and M+. All 8 of these

measurements should be over 1MOhm.

- Again

with everything disconnected, measure the resistance

between the four motor output pins themselves. And again,

all measurements should be over 1MOhm.

- Again

with everything disconnected, measure the resistance from

STEP and DIR to GND and +5V pins. Again, all of these

should read greater than 1MOhm.

- Now

connect just GND and M+. Do not connect anything else to

the ED. The LED should come on and stay on. Measure the

voltage at +5V to GND. It should be right around 5V.

- Now

measure the voltage at each of the four motor output pins

to GND. Two of them should read at about the same voltage

that is at M+ (your power supply voltage - mine is 12V),

and the other two should be almost zero - I measure

0.018V.

- Also check for any missing

components. SparkFun has been known to ship boards

with resistors or capacitors

missing. See the picture above - there is _supposed_

to be one part missing, but only one.

(It's the resistor to the right of the word MOTOR.)

If your board has any missing parts,

it might not work well.

If all of

those measurements pass, it doesn't mean you ED is not smoked,

but it does rule out internal shorts, which is the most common

failure mode for these driver chips.

Q14) But Brian, can't you give us some real

world numbers for power consumption and heat and stuff like that?

A14) Sure! Here you go. Here are some temperatures I

measured.

The test setup was as follows:

- Lab grade power supply powering a v4.4 Easy Driver.

- Current limit pot set to maximum current (750mA/coil) which

was called MIN on silk screen.

- Digilent chipKIT uC32 board running simple AccelStepper sample

program which ramped speed from 0 steps/second (for 2 seconds)

to 2500 steps/second (for 8 seconds) repeating.

- Ambient temp in my lab was 70F (21C).

- For each test I let the system run for about 30 minutes at

each input voltage to stabilize the temps.

- EasyDriver was mounted on a breadboard, and no cooling was

used.

- Temperatures were taken using a calibrated IR thermometer.

- The coil current was measured with a IProber 520 current probe

connected to a Rigol DS11102D scope.

Notes on testing: The coil current is not 750mA for some motors and

input voltages because the coil resistance limits the current, not

the chopping of the driver chip. With the ROB-09238 motor, you can

never reach full current because of the coil resistance. The driver

chip's internal thermal shutdown temp is 329F (165C). With some

combinations of motor and input voltage, the driver chip will go

into thermal cutoff because this internal temperature is achieved

inside the driver chip. I have marked these in the table with

red cell color. When the chip does this, it will cycle the output

drivers to the motor on and off (about 1 second on, 1 second off).

And yes, I exceeded the rated current for ROB-09238 (330mA) and

ROB-10551 (400mA). Normally, you would set the current adjustment

pot so that the EasyDriver delivers the max current that your

particular motor is rated for. But I wanted to show maximum currents

and heating with this table.

Motor = "Stepper

Motor with Cable", SparkFun ROB-09238 (coil

resistance = 32.6 ohms, 32oz-in torque)

|

Input Voltage

|

Power Supply Current

@ rest

|

Power Supply Current

@ 2500 steps/sec

|

Actual Coil Current

@ 2500 steps/sec

|

Motor Temp

|

Driver Chip Temp

|

9V

|

450 mA

|

120 mA

|

138 mA

|

86F (30C)

|

121F (49C)

|

12V

|

600 mA

|

190 mA

|

224 mA

|

113F (45C)

|

152F (67C)

|

24V

|

1.1 A

|

440 mA

|

475 mA

|

217F (103C)

|

213F (101C)

|

30V

|

1.0 A

|

540 mA

|

600 mA

|

225F (107C)

|

240F (116C)

|

Motor = "Stepper

Motor - 68 oz.in", SparkFun ROB-10846 (coil

resistance = 1.8 ohms, 68 oz-in torque)

|

Input Voltage

|

Power Supply Current

@ rest

|

Power Supply Current

@ 2500 steps/sec

|

Actual Coil Current

@ 2500 steps/sec

|

Motor Temp

|

Driver Chip Temp

|

9V

|

470 mA

|

510 mA

|

780 mA

|

83F (28C)

|

266F (130C)

|

12V

|

360 mA

|

390 mA

|

780 mA

|

85F (29C)

|

270F (132C)

|

24V

|

210 mA

|

240 mA

|

780 mA

|

85F (29C)

|

277F (136C) (thermal

limiting)

|

30V

|

210 mA

|

220 mA

|

780 mA

|

85F (29C)

|

277F (136C) (thermal

limiting)

|

Motor = "Small

Stepper Motor", SparkFun ROB-10551 (coil

resistance = 4 ohms)

|

Input Voltage

|

Power Supply Current

@ rest

|

Power Supply Current

@ 2500 steps/sec

|

Actual Coil Current

@ 2500 steps/sec

|

Motor Temp

|

Driver Chip Temp

|

9V

|

650 mA

|

690 mA

|

780 mA

|

98F (36C)

|

263F (128C)

|

12V

|

490 mA

|

580 mA

|

780 mA

|

100F (38C)

|

270F (132C)

|

24V

|

270 mA

|

320 mA

|

780 mA

|

130F (54C)

|

276F (136C)

|

30V

|

250 mA

|

280 mA

|

780 mA

|

135F (57C)

|

282F (139C) (thermal

limiting)

|

Q15) So I see that the EasyDriver has a pin

labeled 5V. What is it for?

A15) Well, based on user's e-mails to me, there is a lot of

confusion about this pin. It is NOT for powering the Easy Driver at

5V. In other words, it is NOT a power input, or input of any kind.

In fact, it's an output pin! Yup, the EasyDriver's 5V regulator has

some extra juice, and so we brought out the 5V output of the

regulator for you to use if you want. This means that you can

connect other things to this pin that need 5V to operate, and the

EasyDriver will power them. To a limit, of course.

So how much power can you pull from the 5V pin before bad things

happen? Well, I really wanted to know - not using calculations, but

some real world experimentation numbers. So I took an EasyDriver and

put a variable resistor across the 5V and GND pins and measured the

temperature of the 5V regulator chip on the EasyDriver as I pulled

more and more current through the 5V pin. Note that this is current

in addition to what's needed to power the A3967 and LED. For each

input voltage (to the M+ and GND pins) I increased the load on the

5V pin until the voltage started to dip from 5.00V indicating the

regulator was going into thermal limit. Here's what I got:

Easy Driver v4.4,

no motor connected to EasyDriver, temperature read with IR

probe on 5V regulator chip, ambient temp = 72F (22C)

|

Input Voltage

|

Current used from 5V pin

|

Regulator Chip Temp

|

9V

|

355 mA

|

(thermal limiting)

|

12V

|

175 mA

|

(thermal limiting)

|

24V

|

26 mA

|

(thermal limiting)

|

Q16) What do the two jumpers do on the

board?

A16) The way I designed the EasyDriver is with a power

supply that can supply either 3.3V or 5V to the EasyDriver's

logic-level power rail (Vcc on the schematic). This allows people

to use the Easy Driver with microcontroller that output either

3.3V or 5V control signals.

The 3/5V jumper (SJ2

on the schematic) comes 'open' from the factory (no connection

between the pads) and thus is supplying 5V to the driver chip,

and thus by default the Easy Driver works with 5V control input

levels.

To use the EasyDriver with 3.3V logic levels, simply solder a

blob of solder on the 3/5V jumper pads. This will set the Vcc on

the Easy Driver to 3.3V.

The other jumper is labeled APWR on the board and is called SJ1

on the schematic. If you look very carefully on your Easy Driver,

you will see a thin copper trace between the two jumper pads. From

the factory, this jumper is 'closed' (i.e. shorted) by that little

piece of copper on the board. So even though there is no solder

blob there, it is in fact shorted.

The purpose of APWR is

to allow users to disconnect the built-in logic power supply of

the EasyDriver and power it using their own 5V or 3.3V logic

level power supply. You might want to do this for power savings

reasons. For example, if you're using a 24V M+ motor power

supply for the EasyDriver, the built-in voltage regulator (IC2

on the schematic) will get very hot because it's dropping that

24V down to 5V and giving up all of that extra voltage as heat.

This is very inefficient and will raise the temperature of the

board.

Instead, if you

already have a 5V power supply in your project (say a switching

power supply that's powering your microcontroller), you can use

that 5V power supply to power the Easy Driver as well as your

other components. The way you do that is to cut that little

trace in the APWR jumper, thus 'opening' the jumper. This will

prevent any power from flowing through the built-in voltage

regulator, thus preventing it from ever heating up. You then

supply 5V (or 3.3V) power to the Easy Driver through the +5V pin

from your external power supply.

If you ever want to

back to using the built-in power supply of the EasyDriver, you

can then solder a blob of solder over the APWR jumper, thus

'closing' it again.

It is very, very rare

for people to use the APWR jumper. So unless you would like to

power the logic side of the Easy Driver from your own power

supply, you can leave it as it is from the factory.

Q17) Does it matter which order I power

things on? Can the Easy Driver be damaged by the order that things

power up?

A17) As far as I know, no. If you have a microcontroller

board (like a chipKIT or Arduino) connected to your Easy Driver, and

the microcontroller is powered from a different power supply than

the BED is (say over USB from a PC), it might seem to make sense

that powering up the microcontroller first would apply voltages to

the Easy Driver pins before the ED is ready for them (since it isn't

powered up yet) and cause damage. Based on my understanding of the

input protection circuitry on the ED, and my extensive testing,

there should be no damage caused in this situation. This answer only

applies to the order in which power is applied to the boards - you

still must not disconnect a motor from a ED that has power.

Questions? E-mail me at

Easy Driver Stepper Motor

Driver

Easy Driver Stepper Motor

Driver